It’s been quite a while since I was able to show you any progress on Étude. The Nordic Tugs factory is not huge and can’t work on many boats at the same time. There are four steps: 1. Cast the hull, cabin and other pieces 2. Install everything

It’s been quite a while since I was able to show you any progress on Étude. The Nordic Tugs factory is not huge and can’t work on many boats at the same time. There are four steps:

Étude’s pieces were out of their molds quite a while ago, but 40-007 was at Step 2 and 40-006 was at I Step 3 so there was no way to make further progress.

Now 40-006 is sold and 40-007 has moved to Step 3, so work resumes on Étude at Step 2. The Nordic Tugs 40, their newest model, has proven to be very popular. Boats 40-009, -010 and -011 are all waiting to begin production. This is in addition to orders for other models. It’s good to see boats being built in the country, with American parts and labor. We buy enough things from China already.

OK, enough background. Here’s where we are today. These are not my photos, they were sent by the Nordic Tugs factory.

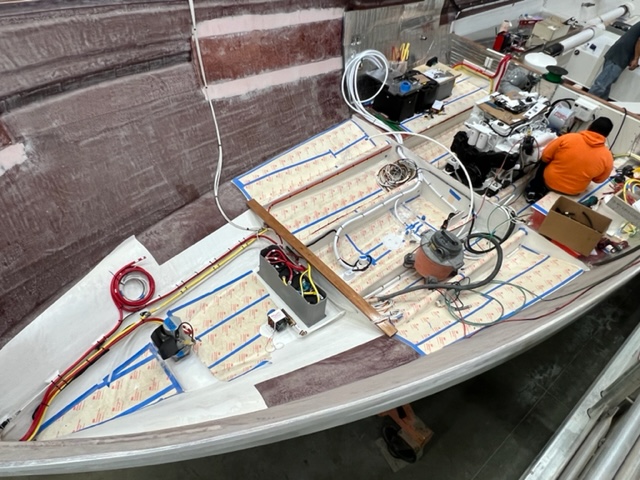

When last we saw the hull, it was empty. Since then, layers of material have been added both for strength and soundproofing. Nordic Tugs builds a custom wiring harness for each boat. Every wire is labeled at both ends. This is a huge benefit for servicing and future modifications.

Here’s a part we’ve been awaiting: the Cummins Diesel engine. Six turbocharged cylinders generating 375hp while meeting the latest emissions specifications.

We are looking at the aft (rear) end. The blue hose is attached to the transmission. The round unit at top on the port (left) side is the air cleaner. To starboard is the turbocharger.

The engine is lowered into place. The default engine for a Nordic Tug is made by Volvo, Cummins is a no-cost option. I did a lot of research before deciding on Cummins. Interestingly the buyers of 40-006, -007 and -009 also chose Cummins. I don’t believe the others have had to decide yet since those boats exist only as spots reserved on the production schedule.

Engine installed! Because Nordic 40s prior to -006 used Volvo engines, there were some kinks to be worked out for the first Cummins installation. I’m glad that they had two boats ahead of Étude to practice on.

The white box at knee level behind the guy in the dark shirt is the 200 US gallon water tank. The tube to starboard is the exhaust pipe. Someday it will connect to the engine.

Nordic calls this wooden construction “The Capsule”. It will contain the midships interior: guest stateroom, head, and shower. When the time is right, it will be lowered into the hull and fiberglassed into place.

We are looking at the Capsule turned upside-down.

We are looking at three pieces. The top of the salon and the top of the pilothouse are glued to the main casting. The pilothouse top is attached with an adhesive that would allow it to be removed — with some effort — should the engine ever have to be hoisted out.

This is not your standard Nordic Tugs mast. It’s “Steve’s special” mast. Why? Because I have more than the usual number of things that I want to mount on it. The long arm at the lower end will hold the radar dome. We will hang our loud hailer beneath it. The smaller platform higher up is for a combination TV/FM antenna. If there’s ever a reason, this could be replaced by a satellite uplink for Internet and TV. I doubt that will ever happen.

At the very top will be an exceedingly bright LED spotlight that can rotate 360 degrees and pan up-and-down. It is controlled from the helm. Behind it on an extension post will be the anchor light.

The two horizontal members are called wings. One will hold a weather station (temperature, wind speed and direction, etc.) the other will hold the antenna for a cellular booster.

Oh yeah, the silver thing is a ventilation hatch. Nice to have fresh air flowing into the pilothouse when underway on a hot day.

That’s it for now. Mary Anne and I will be at the factory in about a week to get a status update and a close look at our boat. Expect another post if there’s enough change to justify one.